The relentless challenge of lunar dust abrasion has pushed material scientists to develop innovative protective coatings for spacecraft and equipment destined for Moon missions. Recent tests conducted at NASA's Glenn Research Center demonstrate significant progress in combating this persistent threat to lunar exploration hardware.

Lunar regolith differs dramatically from terrestrial dust - its jagged, glass-like particles result from billions of years of meteoroid impacts without atmospheric weathering. These microscopic shards cling to surfaces through electrostatic attraction and physically degrade materials through constant abrasion. The Apollo missions documented how this abrasive dust compromised spacesuit joints, scratched helmet visors, and infiltrated equipment seals within days of surface operations.

Material scientists have turned to advanced nanocomposite coatings as the most promising solution. The current research focuses on a proprietary ceramic-polymer hybrid coating that combines the hardness of aluminum oxide ceramics with the flexibility of specialized polyimides. This unique formulation allows the coating to maintain structural integrity during the extreme temperature fluctuations experienced on the lunar surface, ranging from -173°C during lunar night to 127°C in daylight.

Testing methodology developed specifically for lunar conditions subjects coated samples to simulated regolith particles accelerated to velocities matching those expected during rover traverses and landing events. The custom-built tribometer measures microscopic wear patterns using interferometry while exposing materials to vacuum conditions and ultraviolet radiation comparable to the lunar environment.

Initial results show the experimental coating reduces abrasive wear by 78% compared to uncoated aluminum alloys typically used in spacecraft construction. Perhaps more impressively, the coating maintains 92% of its initial effectiveness after exposure to 500 thermal cycles between extreme temperature extremes. This thermal durability addresses one of the most challenging aspects of lunar material performance.

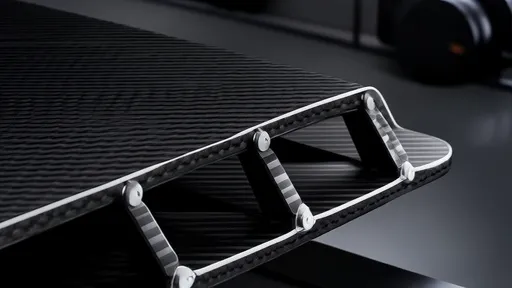

The coating's multilayered architecture represents a significant departure from previous approaches. A bottom layer of porous alumina provides exceptional adhesion to metal substrates, while the middle nanocomposite layer delivers the primary abrasion resistance. The topmost fluorinated polymer layer reduces dust adhesion through low surface energy properties - effectively making the surface "non-stick" to charged lunar particles.

Field testing under more realistic conditions is already underway. Engineers have mounted coated test panels on the lower struts of a prototype lunar lander undergoing mobility trials at the Johnson Space Center's rock yard. Early data from these dynamic tests suggests the coating performs even better than laboratory results predicted when subjected to the combined effects of vibration, dust impingement, and thermal stress.

Parallel development focuses on application techniques suitable for use in lunar conditions. Current prototypes utilize a room-temperature curing process that could theoretically be deployed for field repairs using handheld applicators. This becomes particularly important for long-duration missions where cumulative wear might require periodic recoating of high-abrasion areas.

The implications of this technological advancement extend beyond lunar exploration. Similar coatings could protect equipment destined for Mars, where fine dust presents different but equally challenging problems. The fundamental research into nanoscale abrasion mechanisms also contributes to terrestrial applications, particularly in harsh industrial environments where equipment faces constant particulate exposure.

As Artemis mission planners finalize designs for the next generation of lunar surface systems, these material solutions arrive at a critical juncture. The ability to mitigate dust abrasion directly impacts mission longevity and astronaut safety. With continued successful testing, we may see these coatings become standard protection for everything from rover wheels to habitat airlocks within the next five years.

Industry observers note that solving the lunar dust challenge could accelerate the timeline for sustained lunar operations. When equipment lasts longer between maintenance cycles and requires fewer spare parts, the entire architecture of lunar exploration becomes more sustainable. This coating technology represents more than just a material improvement - it's an enabling technology for humanity's permanent return to the Moon.

The research team continues to refine the formulation, with particular attention to improving performance at the molecular level. Recent atomic force microscopy studies reveal how the coating's nanostructure deforms under stress, providing crucial data for the next iteration of the material. What began as a solution to a very specific technical challenge may well become one of the most broadly applicable material innovations of the early lunar exploration era.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025